Case study: construction market

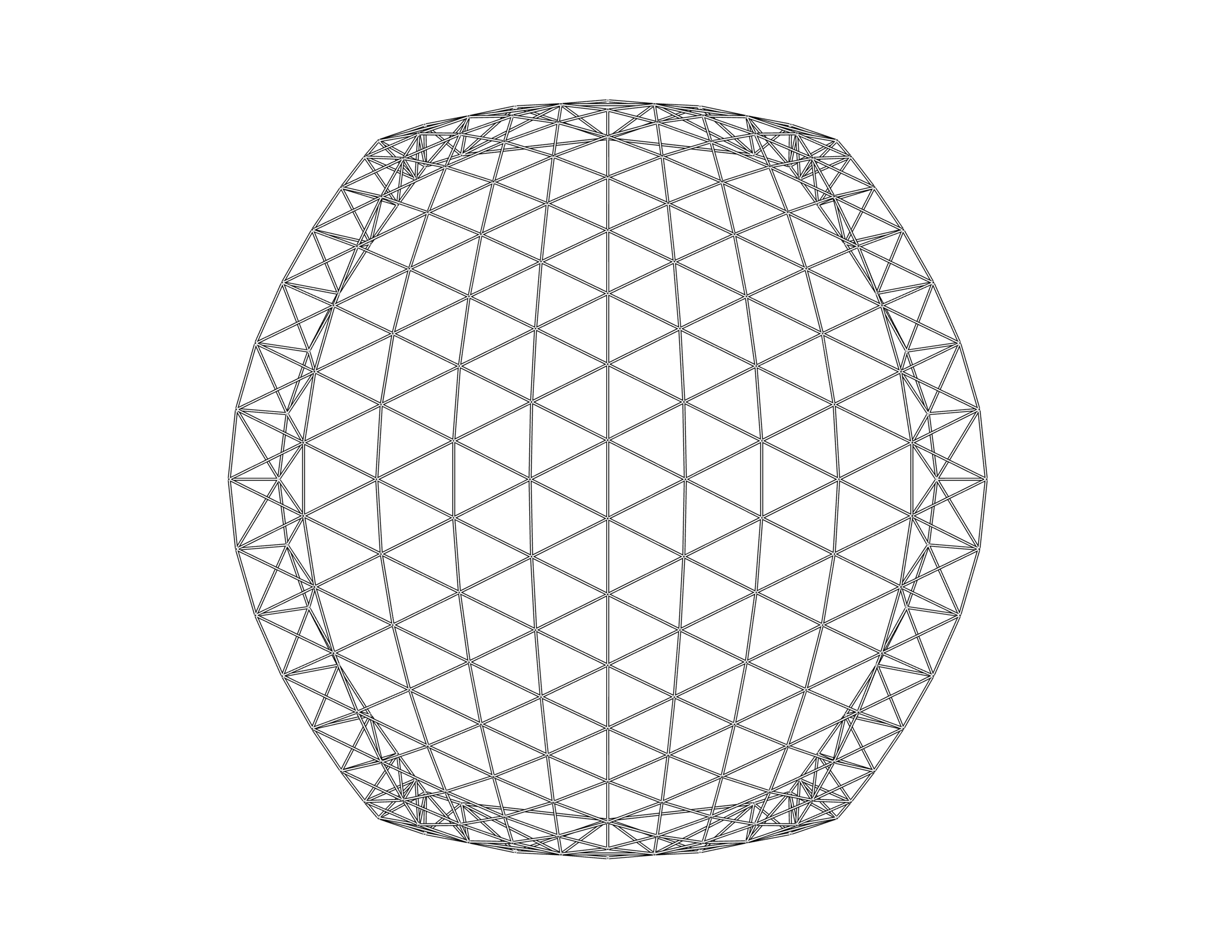

Parametric carport.

Design features

-

Parametric design allows the generation of complex curved lattice with minimum inputs. Our lattice printers allows mass customization at minimal production cost.

-

This particular shape offers extreme material efficiency. The large openings are supported by curved trusses, while a compound curvature dome lets a single layer lattice support large loads with minimal material.

-

There are multiple options for covering the surface, from tiles to cost effective waterproof membranes applied to follow the curvature.

-

A variety of FEA analysis can be run. In this particular example we simulate the impact of extreme wind loading.

Print time (full frame): 5h

Material cost (full frame): $2,000

Up to 5x lower cost

-

Design freedom

Create more innovative designs to inspire your customers. Offer a wider catalog without any of the traditional manufacturing constraints.

-

Extreme speed

Go from sketch to production in hours, not weeks. Expand your catalog and start accepting more custom orders.

-

Environmentally efficient

Consume up to 90% less raw materials. Reduce transportation cost by making it more locally and lightweight.

-

Safe

No welds involved: more predictable strength. The lattice is highly redundant: one failing element will not compromise the structure.

-

Highly automated

Skilled metal workers are hard to find. Focus them on more creative task while our printer take the repetitive work.

-

No special tooling

No need to invest in large specialized machine and custom tooling for each product. You can start producing structures of any scale on day one.

Our lattice printer can also make more traditional linear shapes.

Case study coming soon.